受託業務でできること

求められているものをタイムリーに

お客様のご要望に迅速に対応

電子・電池材料、化粧品原料、セラミックス、樹脂、触媒などの素材を

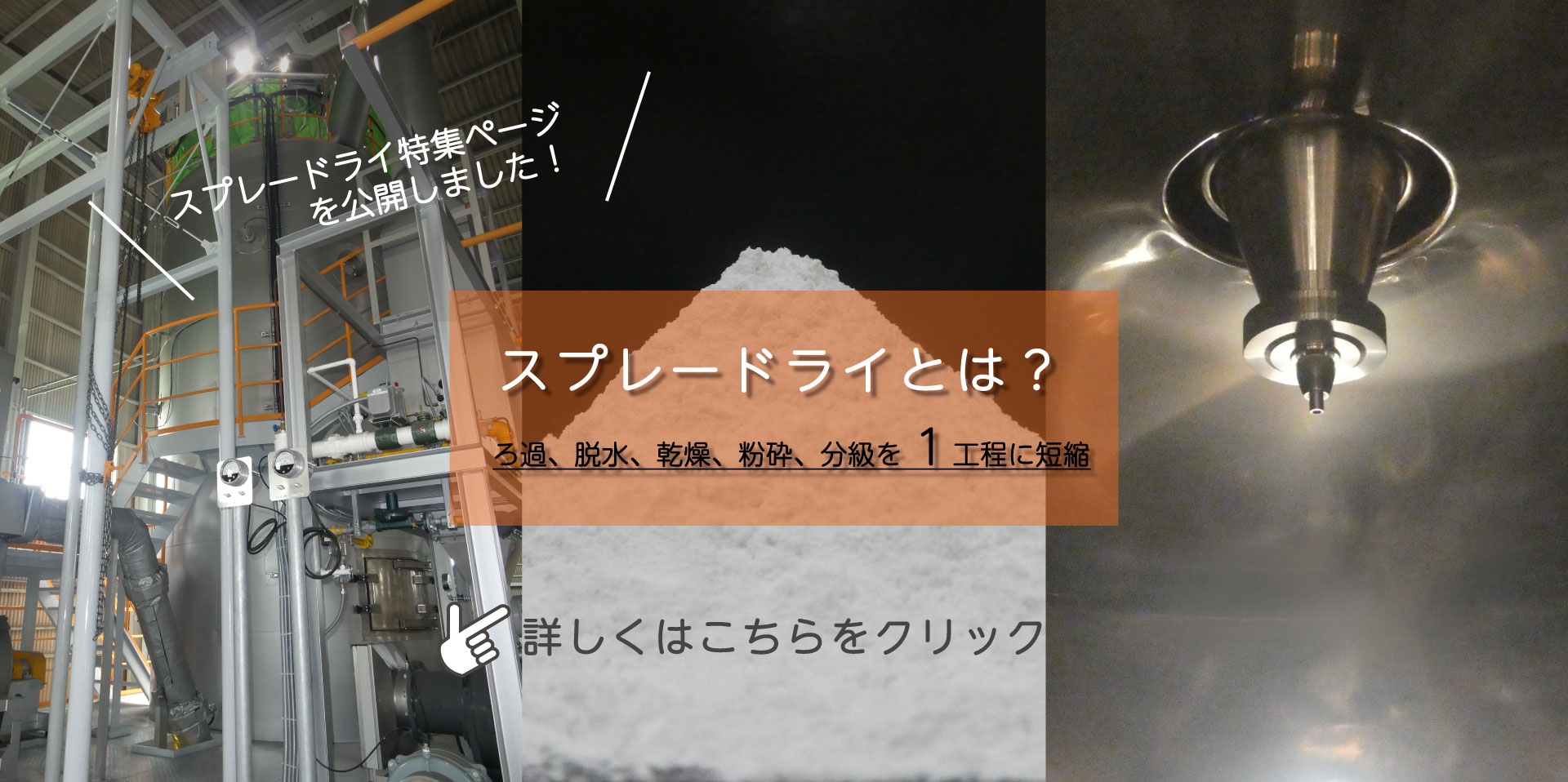

✓スプレードライヤーで造粒

✓フィルタープレスでろ過

✓連続式焼成炉で焼結

など、お客様の目標・条件に合う受託プランをご提案し、実現までサポートします。

設備のご紹介

主要設備としてビーズミル、真空棚段乾燥機、ナウタミキサ、スプレードライヤー、

ドライマイスタ(気流乾燥機)、常圧棚段乾燥機、フィルタープレス、トンネル連続焼成炉、

ローラーハースキルン、クリーンルーム等を有し、微粉砕、分散、混合、ろ過、遠心分離、

乾燥、焼成、粉砕、分級まで幅広い受託生産を行っております。

受託加工事例

多様な設備と技術力で

最適な受託生産を行っております。

多様な設備のある日本カラー工業では「触媒、電子材料用各種化学製品、その他無機・有機製品」などを主に受託生産しております。

これまで長年培ってきた技術力はもちろん、コンプライアンス・機密保持などの体制も整っている日本カラー工業ではお客様の製品分野や製造要求に応じて最適な受託生産をご提供いたします。

お知らせ

-

2026年2月16日

お知らせ

-

2026年1月29日

お知らせ

-

2025年10月27日

お知らせ

-

2025年10月6日

設備関連

Array

(

[0] => Array

(

[detail] => WP_Post Object

(

[ID] => 3514

[post_author] => 3

[post_date] => 2025-11-08 15:45:57

[post_date_gmt] => 2025-11-08 06:45:57

[post_content] =>

[post_title] => 振動篩・超音波振動篩

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => %e6%8c%af%e5%8b%95%e7%af%a9%e3%83%bb%e8%b6%85%e9%9f%b3%e6%b3%a2%e6%8c%af%e5%8b%95%e7%af%a9

[to_ping] =>

[pinged] =>

[post_modified] => 2025-11-08 15:46:51

[post_modified_gmt] => 2025-11-08 06:46:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/?post_type=equipment&p=3514

[menu_order] => 1

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 18

[name] => 分級(篩)

[slug] => break-class

[term_group] => 0

[term_taxonomy_id] => 18

[taxonomy] => equipment_category

[description] => 日本カラー工業には、通常の振動篩だけでなく、超音波振動篩もあり、目詰まりしやすい微粉も分級できます。さらに10,000Gのマグネットを取り付けることで、製品の除鉄の可能です。

[parent] => 15

[count] => 1

[filter] => raw

[term_order] => 2

)

)

[1] => Array

(

[detail] => WP_Post Object

(

[ID] => 3521

[post_author] => 3

[post_date] => 2025-11-08 15:37:38

[post_date_gmt] => 2025-11-08 06:37:38

[post_content] =>

[post_title] => 移動式タンク

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => %e7%a7%bb%e5%8b%95%e5%bc%8f%e3%82%bf%e3%83%b3%e3%82%af

[to_ping] =>

[pinged] =>

[post_modified] => 2025-11-08 15:40:51

[post_modified_gmt] => 2025-11-08 06:40:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/?post_type=equipment&p=3521

[menu_order] => 2

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 11

[name] => ユーティリティー

[slug] => utilities

[term_group] => 0

[term_taxonomy_id] => 11

[taxonomy] => equipment_category

[description] => 生産に必要なイオン交換水を精製する純水装置、各種設備のオーバーヒートを防ぐチラーユニット、環境基準をクリアした排水を行うための排水処理(一部は廃水処理業者様へ依頼する場合もございます)を行っています。安定した受託生産に不可欠な、徹底管理したユーティリティー設備が揃っています。

[parent] => 8

[count] => 3

[filter] => raw

[term_order] => 3

)

)

[2] => Array

(

[detail] => WP_Post Object

(

[ID] => 2905

[post_author] => 1

[post_date] => 2025-09-01 09:00:53

[post_date_gmt] => 2025-09-01 00:00:53

[post_content] =>

[post_title] => 高速乳化・分散機(ホモミクサー)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => %e9%ab%98%e9%80%9f%e4%b9%b3%e5%8c%96%e3%83%bb%e5%88%86%e6%95%a3%e6%a9%9f%ef%bc%88%e3%83%9b%e3%83%a2%e3%83%9f%e3%82%af%e3%82%b5%e3%83%bc%ef%bc%89

[to_ping] =>

[pinged] =>

[post_modified] => 2025-09-05 12:42:12

[post_modified_gmt] => 2025-09-05 03:42:12

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/?post_type=equipment&p=2905

[menu_order] => 3

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 16

[name] => 湿式粉砕・分散(水系、溶剤系)

[slug] => break-liquid

[term_group] => 0

[term_taxonomy_id] => 16

[taxonomy] => equipment_category

[description] => 粉体を溶媒と一緒に粉砕させることで、サブミクロンまで微粉砕。さらに微粒子化した粉体は表面状態が改質され、溶媒液中に分散しやすくなります。危険物取り扱い可能な工場内設置のビーズミルでは、有機溶剤も使用可能です。

[parent] => 15

[count] => 3

[filter] => raw

[term_order] => 3

)

)

[3] => Array

(

[detail] => WP_Post Object

(

[ID] => 1451

[post_author] => 1

[post_date] => 2025-02-19 09:10:45

[post_date_gmt] => 2025-02-19 00:10:45

[post_content] =>

[post_title] => ディスパー・撹拌機

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => %e3%83%87%e3%82%a3%e3%82%b9%e3%83%91%e3%83%bc%e3%83%bb%e6%94%aa%e6%8b%8c%e6%a9%9f

[to_ping] =>

[pinged] =>

[post_modified] => 2025-02-19 15:24:05

[post_modified_gmt] => 2025-02-19 06:24:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/?post_type=equipment&p=1451

[menu_order] => 4

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 3

[name] => 液体混合

[slug] => fusion-liquid

[term_group] => 0

[term_taxonomy_id] => 3

[taxonomy] => equipment_category

[description] => 原料スラリーの攪拌・溶解・分散が可能です。ジャケット付きタンクを併せて使用することで、温水循環で加温しながら製品を溶解することもできます。また、工場内に備え付けの撹拌機(ディスパー、ミキサー)だけでなく、各設備で使用可能な移動式の撹拌機も取り揃えております。

[parent] => 2

[count] => 1

[filter] => raw

[term_order] => 1

)

)

[4] => Array

(

[detail] => WP_Post Object

(

[ID] => 1252

[post_author] => 1

[post_date] => 2024-11-15 09:00:05

[post_date_gmt] => 2024-11-15 00:00:05

[post_content] =>

[post_title] => ACMパルべライザ

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => %e3%83%9e%e3%82%a4%e3%82%af%e3%83%adacm%e3%83%91%e3%83%ab%e3%81%b9%e3%83%a9%e3%82%a4%e3%82%b6

[to_ping] =>

[pinged] =>

[post_modified] => 2024-11-15 14:37:24

[post_modified_gmt] => 2024-11-15 05:37:24

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/?post_type=equipment&p=1252

[menu_order] => 5

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 17

[name] => 乾式粉砕

[slug] => break-dry

[term_group] => 0

[term_taxonomy_id] => 17

[taxonomy] => equipment_category

[description] => 乾式粉砕は湿式粉砕に比較して、短時間・処理量が多く、粗~中砕が得意です。ハンマーによる衝突粉砕、高速回転するピンのミル粉砕等、乾式粉砕できる設備が多くあります。原料粉体の形状、性質に合わせて様々な粉砕方法、設備をご提案いたします。

[parent] => 15

[count] => 9

[filter] => raw

[term_order] => 1

)

)

[5] => Array

(

[detail] => WP_Post Object

(

[ID] => 2975

[post_author] => 2

[post_date] => 2025-09-02 21:40:21

[post_date_gmt] => 2025-09-02 12:40:21

[post_content] =>

[post_title] => サンプルH2_反応槽(耐酸性)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => %e3%82%b5%e3%83%b3%e3%83%97%e3%83%abh2_%e5%8f%8d%e5%bf%9c%e6%a7%bd%ef%bc%88%e8%80%90%e9%85%b8%e6%80%a7%ef%bc%89

[to_ping] =>

[pinged] =>

[post_modified] => 2025-10-27 10:17:29

[post_modified_gmt] => 2025-10-27 01:17:29

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/?post_type=equipment&p=2975

[menu_order] => 6

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[6] => Array

(

[detail] => WP_Post Object

(

[ID] => 1021

[post_author] => 1

[post_date] => 2024-03-25 00:00:59

[post_date_gmt] => 2024-03-24 15:00:59

[post_content] =>

[post_title] => 連続式焼成炉(ローラーハースキルン)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => %e9%80%a3%e7%b6%9a%e5%bc%8f%e7%84%bc%e6%88%90%e7%82%89%ef%bc%88%e3%83%ad%e3%83%bc%e3%83%a9%e3%83%bc%e3%83%8f%e3%83%bc%e3%82%b9%e3%82%ad%e3%83%ab%e3%83%b3%ef%bc%89

[to_ping] =>

[pinged] =>

[post_modified] => 2024-03-25 13:10:50

[post_modified_gmt] => 2024-03-25 04:10:50

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/?post_type=equipment&p=1021

[menu_order] => 10

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 9

[name] => 焼成

[slug] => heat-heat

[term_group] => 0

[term_taxonomy_id] => 9

[taxonomy] => equipment_category

[description] => 焼成は、製品に強度を与えたり(硬質にする)、色味の調整、不要な成分を除去する役割があります。日本カラー工業にある焼成設備の中でも、ローラーハースキルンは、上下から均一に加熱、窒素雰囲気下で焼成することもでき、製品の酸化を防ぐことが可能です。他焼成設備もございますので、ぜひ設備一覧をご覧ください。

[parent] => 8

[count] => 3

[filter] => raw

[term_order] => 1

)

)

[7] => Array

(

[detail] => WP_Post Object

(

[ID] => 818

[post_author] => 1

[post_date] => 2023-11-21 00:00:03

[post_date_gmt] => 2023-11-20 15:00:03

[post_content] =>

[post_title] => 打錠機

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => %e6%89%93%e9%8c%a0%e6%a9%9f

[to_ping] =>

[pinged] =>

[post_modified] => 2023-11-21 16:42:07

[post_modified_gmt] => 2023-11-21 07:42:07

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/?post_type=equipment&p=818

[menu_order] => 11

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 13

[name] => 成形(打錠、造粒、顆粒)

[slug] => dry-build

[term_group] => 0

[term_taxonomy_id] => 13

[taxonomy] => equipment_category

[description] => 粉体原料(一部設備は湿粉も対応可能)を圧密し、ペレット、錠剤、顆粒に成形します。成形することで、製品のかさ密度やハンドリング性(計量しやすさ、粉塵の低減)が向上します。日本カラー工業では、スクリーンを通して押し出す造粒機、円柱型に圧密する打錠機等、様々な成形方法が可能です。

[parent] => 12

[count] => 3

[filter] => raw

[term_order] => 2

)

)

[8] => Array

(

[detail] => WP_Post Object

(

[ID] => 815

[post_author] => 1

[post_date] => 2023-11-21 00:00:35

[post_date_gmt] => 2023-11-20 15:00:35

[post_content] =>

[post_title] => 高速流動混合機(ヘンシェルミキサー)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => %e9%ab%98%e9%80%9f%e6%b5%81%e5%8b%95%e6%b7%b7%e5%90%88%e6%a9%9f%ef%bc%88%e3%83%98%e3%83%b3%e3%82%b7%e3%82%a7%e3%83%ab%e3%83%9f%e3%82%ad%e3%82%b5%e3%83%bc%ef%bc%89

[to_ping] =>

[pinged] =>

[post_modified] => 2023-11-21 14:00:56

[post_modified_gmt] => 2023-11-21 05:00:56

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/?post_type=equipment&p=815

[menu_order] => 12

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 4

[name] => 粉体混合

[slug] => fusion-powder

[term_group] => 0

[term_taxonomy_id] => 4

[taxonomy] => equipment_category

[description] => Vブレンダー、リボンブレンダー、ヘンシェルミキサ―など各種混合設備を使用し、原料(粉体)特性に合わせた均一な混合が可能です。少量向けのサイズもあり、試作・ラボテストから使用することができます。

[parent] => 2

[count] => 4

[filter] => raw

[term_order] => 2

)

)

[9] => Array

(

[detail] => WP_Post Object

(

[ID] => 199

[post_author] => 1

[post_date] => 2023-07-07 00:00:00

[post_date_gmt] => 2023-07-06 15:00:00

[post_content] =>

[post_title] => 微小ビーズ対応横型ビーズミル(ピコミル)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_35

[to_ping] =>

[pinged] =>

[post_modified] => 2024-02-22 11:51:32

[post_modified_gmt] => 2024-02-22 02:51:32

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_35/

[menu_order] => 13

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 16

[name] => 湿式粉砕・分散(水系、溶剤系)

[slug] => break-liquid

[term_group] => 0

[term_taxonomy_id] => 16

[taxonomy] => equipment_category

[description] => 粉体を溶媒と一緒に粉砕させることで、サブミクロンまで微粉砕。さらに微粒子化した粉体は表面状態が改質され、溶媒液中に分散しやすくなります。危険物取り扱い可能な工場内設置のビーズミルでは、有機溶剤も使用可能です。

[parent] => 15

[count] => 3

[filter] => raw

[term_order] => 3

)

)

[10] => Array

(

[detail] => WP_Post Object

(

[ID] => 207

[post_author] => 1

[post_date] => 2019-04-09 16:30:00

[post_date_gmt] => 2019-04-09 07:30:00

[post_content] =>

[post_title] => 真空棚段乾燥機

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => 80_-98kpa

[to_ping] =>

[pinged] =>

[post_modified] => 2025-09-01 19:06:16

[post_modified_gmt] => 2025-09-01 10:06:16

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/80_-98kpa/

[menu_order] => 14

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 14

[name] => 乾燥

[slug] => dry-dry

[term_group] => 0

[term_taxonomy_id] => 14

[taxonomy] => equipment_category

[description] => 原料(湿粉、スラリー)に熱風、蒸気、温水(間接加温)を使って水分を蒸発させます。数多くの設備を所有する日本カラー工業の中でも、特に乾燥設備は種類が豊富。熱に弱い原料の乾燥が得意な真空乾燥機、粉砕・分級も同時に行うドライマイスター、原料スラリーを瞬時に噴霧乾燥するスプレードライヤー等がございます。

[parent] => 12

[count] => 12

[filter] => raw

[term_order] => 1

)

)

[11] => Array

(

[detail] => WP_Post Object

(

[ID] => 201

[post_author] => 1

[post_date] => 2019-04-14 16:17:00

[post_date_gmt] => 2019-04-14 07:17:00

[post_content] =>

[post_title] => バスケットリューザー(造粒機)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_3

[to_ping] =>

[pinged] =>

[post_modified] => 2024-02-22 11:31:05

[post_modified_gmt] => 2024-02-22 02:31:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_3/

[menu_order] => 15

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 13

[name] => 成形(打錠、造粒、顆粒)

[slug] => dry-build

[term_group] => 0

[term_taxonomy_id] => 13

[taxonomy] => equipment_category

[description] => 粉体原料(一部設備は湿粉も対応可能)を圧密し、ペレット、錠剤、顆粒に成形します。成形することで、製品のかさ密度やハンドリング性(計量しやすさ、粉塵の低減)が向上します。日本カラー工業では、スクリーンを通して押し出す造粒機、円柱型に圧密する打錠機等、様々な成形方法が可能です。

[parent] => 12

[count] => 3

[filter] => raw

[term_order] => 2

)

)

[12] => Array

(

[detail] => WP_Post Object

(

[ID] => 203

[post_author] => 1

[post_date] => 2019-04-12 14:30:00

[post_date_gmt] => 2019-04-12 05:30:00

[post_content] =>

[post_title] => フェザーミル

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_14

[to_ping] =>

[pinged] =>

[post_modified] => 2024-02-22 11:36:47

[post_modified_gmt] => 2024-02-22 02:36:47

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_14/

[menu_order] => 16

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 17

[name] => 乾式粉砕

[slug] => break-dry

[term_group] => 0

[term_taxonomy_id] => 17

[taxonomy] => equipment_category

[description] => 乾式粉砕は湿式粉砕に比較して、短時間・処理量が多く、粗~中砕が得意です。ハンマーによる衝突粉砕、高速回転するピンのミル粉砕等、乾式粉砕できる設備が多くあります。原料粉体の形状、性質に合わせて様々な粉砕方法、設備をご提案いたします。

[parent] => 15

[count] => 9

[filter] => raw

[term_order] => 1

)

)

[13] => Array

(

[detail] => WP_Post Object

(

[ID] => 204

[post_author] => 1

[post_date] => 2019-04-11 16:22:00

[post_date_gmt] => 2019-04-11 07:22:00

[post_content] =>

[post_title] => ローラーコンパクター(連続造粒機)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_6

[to_ping] =>

[pinged] =>

[post_modified] => 2024-02-22 11:43:05

[post_modified_gmt] => 2024-02-22 02:43:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_6/

[menu_order] => 17

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 13

[name] => 成形(打錠、造粒、顆粒)

[slug] => dry-build

[term_group] => 0

[term_taxonomy_id] => 13

[taxonomy] => equipment_category

[description] => 粉体原料(一部設備は湿粉も対応可能)を圧密し、ペレット、錠剤、顆粒に成形します。成形することで、製品のかさ密度やハンドリング性(計量しやすさ、粉塵の低減)が向上します。日本カラー工業では、スクリーンを通して押し出す造粒機、円柱型に圧密する打錠機等、様々な成形方法が可能です。

[parent] => 12

[count] => 3

[filter] => raw

[term_order] => 2

)

)

[14] => Array

(

[detail] => WP_Post Object

(

[ID] => 205

[post_author] => 1

[post_date] => 2019-04-11 14:31:00

[post_date_gmt] => 2019-04-11 05:31:00

[post_content] =>

[post_title] => アトマイザー(乾式粉砕機)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_15

[to_ping] =>

[pinged] =>

[post_modified] => 2024-02-22 11:53:45

[post_modified_gmt] => 2024-02-22 02:53:45

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_15/

[menu_order] => 18

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 17

[name] => 乾式粉砕

[slug] => break-dry

[term_group] => 0

[term_taxonomy_id] => 17

[taxonomy] => equipment_category

[description] => 乾式粉砕は湿式粉砕に比較して、短時間・処理量が多く、粗~中砕が得意です。ハンマーによる衝突粉砕、高速回転するピンのミル粉砕等、乾式粉砕できる設備が多くあります。原料粉体の形状、性質に合わせて様々な粉砕方法、設備をご提案いたします。

[parent] => 15

[count] => 9

[filter] => raw

[term_order] => 1

)

)

[15] => Array

(

[detail] => WP_Post Object

(

[ID] => 206

[post_author] => 1

[post_date] => 2019-04-10 14:32:00

[post_date_gmt] => 2019-04-10 05:32:00

[post_content] =>

[post_title] => マイクロパルぺライザー(ホソカワ)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_16

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:46:42

[post_modified_gmt] => 2023-09-13 09:46:42

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_16/

[menu_order] => 19

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 17

[name] => 乾式粉砕

[slug] => break-dry

[term_group] => 0

[term_taxonomy_id] => 17

[taxonomy] => equipment_category

[description] => 乾式粉砕は湿式粉砕に比較して、短時間・処理量が多く、粗~中砕が得意です。ハンマーによる衝突粉砕、高速回転するピンのミル粉砕等、乾式粉砕できる設備が多くあります。原料粉体の形状、性質に合わせて様々な粉砕方法、設備をご提案いたします。

[parent] => 15

[count] => 9

[filter] => raw

[term_order] => 1

)

)

[16] => Array

(

[detail] => WP_Post Object

(

[ID] => 209

[post_author] => 1

[post_date] => 2019-04-08 16:31:00

[post_date_gmt] => 2019-04-08 07:31:00

[post_content] =>

[post_title] => スプレードライヤー(1号機)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_8

[to_ping] =>

[pinged] =>

[post_modified] => 2024-03-25 15:56:14

[post_modified_gmt] => 2024-03-25 06:56:14

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_8/

[menu_order] => 20

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 14

[name] => 乾燥

[slug] => dry-dry

[term_group] => 0

[term_taxonomy_id] => 14

[taxonomy] => equipment_category

[description] => 原料(湿粉、スラリー)に熱風、蒸気、温水(間接加温)を使って水分を蒸発させます。数多くの設備を所有する日本カラー工業の中でも、特に乾燥設備は種類が豊富。熱に弱い原料の乾燥が得意な真空乾燥機、粉砕・分級も同時に行うドライマイスター、原料スラリーを瞬時に噴霧乾燥するスプレードライヤー等がございます。

[parent] => 12

[count] => 12

[filter] => raw

[term_order] => 1

)

)

[17] => Array

(

[detail] => WP_Post Object

(

[ID] => 208

[post_author] => 1

[post_date] => 2019-04-09 14:32:00

[post_date_gmt] => 2019-04-09 05:32:00

[post_content] =>

[post_title] => ピンミル(KOLLOPLEX)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => _250z

[to_ping] =>

[pinged] =>

[post_modified] => 2024-11-15 16:06:07

[post_modified_gmt] => 2024-11-15 07:06:07

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/_250z/

[menu_order] => 21

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 17

[name] => 乾式粉砕

[slug] => break-dry

[term_group] => 0

[term_taxonomy_id] => 17

[taxonomy] => equipment_category

[description] => 乾式粉砕は湿式粉砕に比較して、短時間・処理量が多く、粗~中砕が得意です。ハンマーによる衝突粉砕、高速回転するピンのミル粉砕等、乾式粉砕できる設備が多くあります。原料粉体の形状、性質に合わせて様々な粉砕方法、設備をご提案いたします。

[parent] => 15

[count] => 9

[filter] => raw

[term_order] => 1

)

)

[18] => Array

(

[detail] => WP_Post Object

(

[ID] => 212

[post_author] => 1

[post_date] => 2019-04-07 16:32:00

[post_date_gmt] => 2019-04-07 07:32:00

[post_content] =>

[post_title] => スプレードライヤー(2号機)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_9

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:31:54

[post_modified_gmt] => 2023-09-13 09:31:54

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_9/

[menu_order] => 22

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 14

[name] => 乾燥

[slug] => dry-dry

[term_group] => 0

[term_taxonomy_id] => 14

[taxonomy] => equipment_category

[description] => 原料(湿粉、スラリー)に熱風、蒸気、温水(間接加温)を使って水分を蒸発させます。数多くの設備を所有する日本カラー工業の中でも、特に乾燥設備は種類が豊富。熱に弱い原料の乾燥が得意な真空乾燥機、粉砕・分級も同時に行うドライマイスター、原料スラリーを瞬時に噴霧乾燥するスプレードライヤー等がございます。

[parent] => 12

[count] => 12

[filter] => raw

[term_order] => 1

)

)

[19] => Array

(

[detail] => WP_Post Object

(

[ID] => 211

[post_author] => 1

[post_date] => 2019-04-08 14:33:00

[post_date_gmt] => 2019-04-08 05:33:00

[post_content] =>

[post_title] => ピンミル

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => _160z

[to_ping] =>

[pinged] =>

[post_modified] => 2024-11-15 16:19:44

[post_modified_gmt] => 2024-11-15 07:19:44

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/_160z/

[menu_order] => 23

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 17

[name] => 乾式粉砕

[slug] => break-dry

[term_group] => 0

[term_taxonomy_id] => 17

[taxonomy] => equipment_category

[description] => 乾式粉砕は湿式粉砕に比較して、短時間・処理量が多く、粗~中砕が得意です。ハンマーによる衝突粉砕、高速回転するピンのミル粉砕等、乾式粉砕できる設備が多くあります。原料粉体の形状、性質に合わせて様々な粉砕方法、設備をご提案いたします。

[parent] => 15

[count] => 9

[filter] => raw

[term_order] => 1

)

)

[20] => Array

(

[detail] => WP_Post Object

(

[ID] => 1042

[post_author] => 1

[post_date] => 2024-05-22 15:00:40

[post_date_gmt] => 2024-05-22 06:00:40

[post_content] =>

[post_title] => スプレードライヤー(6号機)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => %e3%82%b9%e3%83%97%e3%83%ac%e3%83%bc%e3%83%89%e3%83%a9%e3%82%a4%e3%83%a4%e3%83%bc%ef%bc%883%e5%8f%b7%e6%a9%9f%ef%bc%89

[to_ping] =>

[pinged] =>

[post_modified] => 2025-09-05 12:45:01

[post_modified_gmt] => 2025-09-05 03:45:01

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/?post_type=equipment&p=1042

[menu_order] => 24

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 14

[name] => 乾燥

[slug] => dry-dry

[term_group] => 0

[term_taxonomy_id] => 14

[taxonomy] => equipment_category

[description] => 原料(湿粉、スラリー)に熱風、蒸気、温水(間接加温)を使って水分を蒸発させます。数多くの設備を所有する日本カラー工業の中でも、特に乾燥設備は種類が豊富。熱に弱い原料の乾燥が得意な真空乾燥機、粉砕・分級も同時に行うドライマイスター、原料スラリーを瞬時に噴霧乾燥するスプレードライヤー等がございます。

[parent] => 12

[count] => 12

[filter] => raw

[term_order] => 1

)

)

[21] => Array

(

[detail] => WP_Post Object

(

[ID] => 214

[post_author] => 1

[post_date] => 2019-04-06 16:33:00

[post_date_gmt] => 2019-04-06 07:33:00

[post_content] =>

[post_title] => スプレードライヤー(3号機)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_10

[to_ping] =>

[pinged] =>

[post_modified] => 2024-03-25 15:53:38

[post_modified_gmt] => 2024-03-25 06:53:38

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_10/

[menu_order] => 25

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 14

[name] => 乾燥

[slug] => dry-dry

[term_group] => 0

[term_taxonomy_id] => 14

[taxonomy] => equipment_category

[description] => 原料(湿粉、スラリー)に熱風、蒸気、温水(間接加温)を使って水分を蒸発させます。数多くの設備を所有する日本カラー工業の中でも、特に乾燥設備は種類が豊富。熱に弱い原料の乾燥が得意な真空乾燥機、粉砕・分級も同時に行うドライマイスター、原料スラリーを瞬時に噴霧乾燥するスプレードライヤー等がございます。

[parent] => 12

[count] => 12

[filter] => raw

[term_order] => 1

)

)

[22] => Array

(

[detail] => WP_Post Object

(

[ID] => 213

[post_author] => 1

[post_date] => 2019-04-07 14:34:00

[post_date_gmt] => 2019-04-07 05:34:00

[post_content] =>

[post_title] => オリエント竪型粗砕機 VM-22

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => _vm-22

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:49:25

[post_modified_gmt] => 2023-09-13 09:49:25

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/_vm-22/

[menu_order] => 26

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 17

[name] => 乾式粉砕

[slug] => break-dry

[term_group] => 0

[term_taxonomy_id] => 17

[taxonomy] => equipment_category

[description] => 乾式粉砕は湿式粉砕に比較して、短時間・処理量が多く、粗~中砕が得意です。ハンマーによる衝突粉砕、高速回転するピンのミル粉砕等、乾式粉砕できる設備が多くあります。原料粉体の形状、性質に合わせて様々な粉砕方法、設備をご提案いたします。

[parent] => 15

[count] => 9

[filter] => raw

[term_order] => 1

)

)

[23] => Array

(

[detail] => WP_Post Object

(

[ID] => 215

[post_author] => 1

[post_date] => 2019-04-05 16:34:00

[post_date_gmt] => 2019-04-05 07:34:00

[post_content] =>

[post_title] => 気流乾燥機(ドライマイスター)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_11

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:33:49

[post_modified_gmt] => 2023-09-13 09:33:49

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_11/

[menu_order] => 27

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 14

[name] => 乾燥

[slug] => dry-dry

[term_group] => 0

[term_taxonomy_id] => 14

[taxonomy] => equipment_category

[description] => 原料(湿粉、スラリー)に熱風、蒸気、温水(間接加温)を使って水分を蒸発させます。数多くの設備を所有する日本カラー工業の中でも、特に乾燥設備は種類が豊富。熱に弱い原料の乾燥が得意な真空乾燥機、粉砕・分級も同時に行うドライマイスター、原料スラリーを瞬時に噴霧乾燥するスプレードライヤー等がございます。

[parent] => 12

[count] => 12

[filter] => raw

[term_order] => 1

)

)

[24] => Array

(

[detail] => WP_Post Object

(

[ID] => 791

[post_author] => 1

[post_date] => 2019-04-05 04:33:34

[post_date_gmt] => 2019-04-04 19:33:34

[post_content] =>

[post_title] => 円錐形攪拌型乾燥機(ナウタミキサ)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => %e5%86%86%e9%8c%90%e5%bd%a2%e6%94%aa%e6%8b%8c%e5%9e%8b%e4%b9%be%e7%87%a5%e6%a9%9f%ef%bc%88%e3%83%8a%e3%82%a6%e3%82%bf%e3%83%9f%e3%82%ad%e3%82%b5%ef%bc%89

[to_ping] =>

[pinged] =>

[post_modified] => 2023-10-25 14:59:14

[post_modified_gmt] => 2023-10-25 05:59:14

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/?post_type=equipment&p=791

[menu_order] => 28

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 14

[name] => 乾燥

[slug] => dry-dry

[term_group] => 0

[term_taxonomy_id] => 14

[taxonomy] => equipment_category

[description] => 原料(湿粉、スラリー)に熱風、蒸気、温水(間接加温)を使って水分を蒸発させます。数多くの設備を所有する日本カラー工業の中でも、特に乾燥設備は種類が豊富。熱に弱い原料の乾燥が得意な真空乾燥機、粉砕・分級も同時に行うドライマイスター、原料スラリーを瞬時に噴霧乾燥するスプレードライヤー等がございます。

[parent] => 12

[count] => 12

[filter] => raw

[term_order] => 1

)

)

[25] => Array

(

[detail] => WP_Post Object

(

[ID] => 216

[post_author] => 1

[post_date] => 2019-04-05 16:23:00

[post_date_gmt] => 2019-04-05 07:23:00

[post_content] =>

[post_title] => 全自動プッシャー式連続焼成炉

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_7

[to_ping] =>

[pinged] =>

[post_modified] => 2024-11-15 15:53:57

[post_modified_gmt] => 2024-11-15 06:53:57

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_7/

[menu_order] => 29

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 9

[name] => 焼成

[slug] => heat-heat

[term_group] => 0

[term_taxonomy_id] => 9

[taxonomy] => equipment_category

[description] => 焼成は、製品に強度を与えたり(硬質にする)、色味の調整、不要な成分を除去する役割があります。日本カラー工業にある焼成設備の中でも、ローラーハースキルンは、上下から均一に加熱、窒素雰囲気下で焼成することもでき、製品の酸化を防ぐことが可能です。他焼成設備もございますので、ぜひ設備一覧をご覧ください。

[parent] => 8

[count] => 3

[filter] => raw

[term_order] => 1

)

)

[26] => Array

(

[detail] => WP_Post Object

(

[ID] => 238

[post_author] => 1

[post_date] => 2019-04-01 15:14:00

[post_date_gmt] => 2019-04-01 06:14:00

[post_content] =>

[post_title] => クリーンブース危険物製造所 80㎡×1室

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => 801

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:11:52

[post_modified_gmt] => 2023-09-13 09:11:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/801/

[menu_order] => 30

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 5

[name] => クリーンブース

[slug] => fusion-clean

[term_group] => 0

[term_taxonomy_id] => 5

[taxonomy] => equipment_category

[description] => 有機溶剤が使用可能な工場内に、クラス10,000のクリーンルームがあります。電子材料用など微細な異物を嫌う製品の生産が可能です。

[parent] => 2

[count] => 3

[filter] => raw

[term_order] => 3

)

)

[27] => Array

(

[detail] => WP_Post Object

(

[ID] => 220

[post_author] => 1

[post_date] => 2019-04-04 15:06:00

[post_date_gmt] => 2019-04-04 06:06:00

[post_content] =>

[post_title] => フィルタープレス

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_26

[to_ping] =>

[pinged] =>

[post_modified] => 2025-02-19 15:27:32

[post_modified_gmt] => 2025-02-19 06:27:32

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_26/

[menu_order] => 31

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 7

[name] => 脱水・洗浄

[slug] => clean-dry

[term_group] => 0

[term_taxonomy_id] => 7

[taxonomy] => equipment_category

[description] => 日本カラー工業でできる脱水(固液分離)・洗浄は、少量・難濾過性原料向けの上排型脱水機や横型フィルター反転式遠心分離機、一度に多くの処理量が求められる製品にはフィルタープレスがあります。無機、有機問わず反応後の未反応物や不純物を取り除いたり、また、固形濃度が低いスラリーからの製品回収にも効果を発揮します。

[parent] => 6

[count] => 3

[filter] => raw

[term_order] => 1

)

)

[28] => Array

(

[detail] => WP_Post Object

(

[ID] => 232

[post_author] => 1

[post_date] => 2019-04-02 15:13:00

[post_date_gmt] => 2019-04-02 06:13:00

[post_content] =>

[post_title] => クリーンブース危険物製造所 17.5㎡×1室

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => 1752

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:17:29

[post_modified_gmt] => 2023-09-13 09:17:29

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/1752/

[menu_order] => 32

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 5

[name] => クリーンブース

[slug] => fusion-clean

[term_group] => 0

[term_taxonomy_id] => 5

[taxonomy] => equipment_category

[description] => 有機溶剤が使用可能な工場内に、クラス10,000のクリーンルームがあります。電子材料用など微細な異物を嫌う製品の生産が可能です。

[parent] => 2

[count] => 3

[filter] => raw

[term_order] => 3

)

)

[29] => Array

(

[detail] => WP_Post Object

(

[ID] => 222

[post_author] => 1

[post_date] => 2019-04-04 14:53:00

[post_date_gmt] => 2019-04-04 05:53:00

[post_content] =>

[post_title] => パワーミル

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_17

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:50:53

[post_modified_gmt] => 2023-09-13 09:50:53

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_17/

[menu_order] => 33

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 17

[name] => 乾式粉砕

[slug] => break-dry

[term_group] => 0

[term_taxonomy_id] => 17

[taxonomy] => equipment_category

[description] => 乾式粉砕は湿式粉砕に比較して、短時間・処理量が多く、粗~中砕が得意です。ハンマーによる衝突粉砕、高速回転するピンのミル粉砕等、乾式粉砕できる設備が多くあります。原料粉体の形状、性質に合わせて様々な粉砕方法、設備をご提案いたします。

[parent] => 15

[count] => 9

[filter] => raw

[term_order] => 1

)

)

[30] => Array

(

[detail] => WP_Post Object

(

[ID] => 223

[post_author] => 1

[post_date] => 2019-04-03 16:57:00

[post_date_gmt] => 2019-04-03 07:57:00

[post_content] =>

[post_title] => 棚段乾燥機(棚段固定式)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_12

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:35:20

[post_modified_gmt] => 2023-09-13 09:35:20

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_12/

[menu_order] => 34

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 14

[name] => 乾燥

[slug] => dry-dry

[term_group] => 0

[term_taxonomy_id] => 14

[taxonomy] => equipment_category

[description] => 原料(湿粉、スラリー)に熱風、蒸気、温水(間接加温)を使って水分を蒸発させます。数多くの設備を所有する日本カラー工業の中でも、特に乾燥設備は種類が豊富。熱に弱い原料の乾燥が得意な真空乾燥機、粉砕・分級も同時に行うドライマイスター、原料スラリーを瞬時に噴霧乾燥するスプレードライヤー等がございます。

[parent] => 12

[count] => 12

[filter] => raw

[term_order] => 1

)

)

[31] => Array

(

[detail] => WP_Post Object

(

[ID] => 225

[post_author] => 1

[post_date] => 2019-04-03 15:13:00

[post_date_gmt] => 2019-04-03 06:13:00

[post_content] =>

[post_title] => クリーンブース 17.5㎡×1室

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => 541

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:18:20

[post_modified_gmt] => 2023-09-13 09:18:20

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/541/

[menu_order] => 35

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 5

[name] => クリーンブース

[slug] => fusion-clean

[term_group] => 0

[term_taxonomy_id] => 5

[taxonomy] => equipment_category

[description] => 有機溶剤が使用可能な工場内に、クラス10,000のクリーンルームがあります。電子材料用など微細な異物を嫌う製品の生産が可能です。

[parent] => 2

[count] => 3

[filter] => raw

[term_order] => 3

)

)

[32] => Array

(

[detail] => WP_Post Object

(

[ID] => 226

[post_author] => 1

[post_date] => 2019-04-03 15:07:00

[post_date_gmt] => 2019-04-03 06:07:00

[post_content] =>

[post_title] => 上排型脱水機

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_27

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:20:04

[post_modified_gmt] => 2023-09-13 09:20:04

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_27/

[menu_order] => 36

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 7

[name] => 脱水・洗浄

[slug] => clean-dry

[term_group] => 0

[term_taxonomy_id] => 7

[taxonomy] => equipment_category

[description] => 日本カラー工業でできる脱水(固液分離)・洗浄は、少量・難濾過性原料向けの上排型脱水機や横型フィルター反転式遠心分離機、一度に多くの処理量が求められる製品にはフィルタープレスがあります。無機、有機問わず反応後の未反応物や不純物を取り除いたり、また、固形濃度が低いスラリーからの製品回収にも効果を発揮します。

[parent] => 6

[count] => 3

[filter] => raw

[term_order] => 1

)

)

[33] => Array

(

[detail] => WP_Post Object

(

[ID] => 227

[post_author] => 1

[post_date] => 2019-04-03 15:03:00

[post_date_gmt] => 2019-04-03 06:03:00

[post_content] =>

[post_title] => 反応槽SUS304

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => sus304

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:23:26

[post_modified_gmt] => 2023-09-13 09:23:26

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/sus304/

[menu_order] => 37

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 10

[name] => 反応層

[slug] => heat-reaction

[term_group] => 0

[term_taxonomy_id] => 10

[taxonomy] => equipment_category

[description] => 36L容量のタンク~耐酸性に優れたGL(グラスライニング)層まで幅広いラインナップ。ジャケット付きのタンク・反応層もございますので、液体原料を加温することも可能です。

[parent] => 8

[count] => 3

[filter] => raw

[term_order] => 2

)

)

[34] => Array

(

[detail] => WP_Post Object

(

[ID] => 217

[post_author] => 1

[post_date] => 2019-04-05 14:58:00

[post_date_gmt] => 2019-04-05 05:58:00

[post_content] =>

[post_title] => リボンブレンダー

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_21

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-12 17:22:57

[post_modified_gmt] => 2023-09-12 08:22:57

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_21/

[menu_order] => 38

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 4

[name] => 粉体混合

[slug] => fusion-powder

[term_group] => 0

[term_taxonomy_id] => 4

[taxonomy] => equipment_category

[description] => Vブレンダー、リボンブレンダー、ヘンシェルミキサ―など各種混合設備を使用し、原料(粉体)特性に合わせた均一な混合が可能です。少量向けのサイズもあり、試作・ラボテストから使用することができます。

[parent] => 2

[count] => 4

[filter] => raw

[term_order] => 2

)

)

[35] => Array

(

[detail] => WP_Post Object

(

[ID] => 229

[post_author] => 1

[post_date] => 2019-04-03 14:55:00

[post_date_gmt] => 2019-04-03 05:55:00

[post_content] =>

[post_title] => スクリーン使用衝撃式粉砕機(マキノ式粉砕機)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_18

[to_ping] =>

[pinged] =>

[post_modified] => 2025-03-10 15:25:44

[post_modified_gmt] => 2025-03-10 06:25:44

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_18/

[menu_order] => 39

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 17

[name] => 乾式粉砕

[slug] => break-dry

[term_group] => 0

[term_taxonomy_id] => 17

[taxonomy] => equipment_category

[description] => 乾式粉砕は湿式粉砕に比較して、短時間・処理量が多く、粗~中砕が得意です。ハンマーによる衝突粉砕、高速回転するピンのミル粉砕等、乾式粉砕できる設備が多くあります。原料粉体の形状、性質に合わせて様々な粉砕方法、設備をご提案いたします。

[parent] => 15

[count] => 9

[filter] => raw

[term_order] => 1

)

)

[36] => Array

(

[detail] => WP_Post Object

(

[ID] => 230

[post_author] => 1

[post_date] => 2019-04-02 16:58:00

[post_date_gmt] => 2019-04-02 07:58:00

[post_content] =>

[post_title] => 棚段乾燥機(棚移動式)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_13

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:36:33

[post_modified_gmt] => 2023-09-13 09:36:33

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_13/

[menu_order] => 40

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 14

[name] => 乾燥

[slug] => dry-dry

[term_group] => 0

[term_taxonomy_id] => 14

[taxonomy] => equipment_category

[description] => 原料(湿粉、スラリー)に熱風、蒸気、温水(間接加温)を使って水分を蒸発させます。数多くの設備を所有する日本カラー工業の中でも、特に乾燥設備は種類が豊富。熱に弱い原料の乾燥が得意な真空乾燥機、粉砕・分級も同時に行うドライマイスター、原料スラリーを瞬時に噴霧乾燥するスプレードライヤー等がございます。

[parent] => 12

[count] => 12

[filter] => raw

[term_order] => 1

)

)

[37] => Array

(

[detail] => WP_Post Object

(

[ID] => 231

[post_author] => 1

[post_date] => 2019-04-02 16:57:00

[post_date_gmt] => 2019-04-02 07:57:00

[post_content] =>

[post_title] => 横型ビーズミル (ダイノーミル・ウルトラビスコミル)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_1

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:54:15

[post_modified_gmt] => 2023-09-13 09:54:15

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_1/

[menu_order] => 41

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 16

[name] => 湿式粉砕・分散(水系、溶剤系)

[slug] => break-liquid

[term_group] => 0

[term_taxonomy_id] => 16

[taxonomy] => equipment_category

[description] => 粉体を溶媒と一緒に粉砕させることで、サブミクロンまで微粉砕。さらに微粒子化した粉体は表面状態が改質され、溶媒液中に分散しやすくなります。危険物取り扱い可能な工場内設置のビーズミルでは、有機溶剤も使用可能です。

[parent] => 15

[count] => 3

[filter] => raw

[term_order] => 3

)

)

[38] => Array

(

[detail] => WP_Post Object

(

[ID] => 233

[post_author] => 1

[post_date] => 2019-04-02 15:11:00

[post_date_gmt] => 2019-04-02 06:11:00

[post_content] =>

[post_title] => 純水(イオン交換水)製造装置

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_30

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:22:09

[post_modified_gmt] => 2023-09-13 09:22:09

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_30/

[menu_order] => 42

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 11

[name] => ユーティリティー

[slug] => utilities

[term_group] => 0

[term_taxonomy_id] => 11

[taxonomy] => equipment_category

[description] => 生産に必要なイオン交換水を精製する純水装置、各種設備のオーバーヒートを防ぐチラーユニット、環境基準をクリアした排水を行うための排水処理(一部は廃水処理業者様へ依頼する場合もございます)を行っています。安定した受託生産に不可欠な、徹底管理したユーティリティー設備が揃っています。

[parent] => 8

[count] => 3

[filter] => raw

[term_order] => 3

)

)

[39] => Array

(

[detail] => WP_Post Object

(

[ID] => 234

[post_author] => 1

[post_date] => 2019-04-02 15:04:00

[post_date_gmt] => 2019-04-02 06:04:00

[post_content] =>

[post_title] => 円筒堅型密閉GL

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => gl

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:24:06

[post_modified_gmt] => 2023-09-13 09:24:06

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/gl/

[menu_order] => 43

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 10

[name] => 反応層

[slug] => heat-reaction

[term_group] => 0

[term_taxonomy_id] => 10

[taxonomy] => equipment_category

[description] => 36L容量のタンク~耐酸性に優れたGL(グラスライニング)層まで幅広いラインナップ。ジャケット付きのタンク・反応層もございますので、液体原料を加温することも可能です。

[parent] => 8

[count] => 3

[filter] => raw

[term_order] => 2

)

)

[40] => Array

(

[detail] => WP_Post Object

(

[ID] => 236

[post_author] => 1

[post_date] => 2019-04-01 16:59:00

[post_date_gmt] => 2019-04-01 07:59:00

[post_content] =>

[post_title] => コニカルドライヤー(真空引き可)(真空度 -95kPa)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => _-95kpa

[to_ping] =>

[pinged] =>

[post_modified] => 2024-11-15 15:48:12

[post_modified_gmt] => 2024-11-15 06:48:12

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/_-95kpa/

[menu_order] => 45

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 14

[name] => 乾燥

[slug] => dry-dry

[term_group] => 0

[term_taxonomy_id] => 14

[taxonomy] => equipment_category

[description] => 原料(湿粉、スラリー)に熱風、蒸気、温水(間接加温)を使って水分を蒸発させます。数多くの設備を所有する日本カラー工業の中でも、特に乾燥設備は種類が豊富。熱に弱い原料の乾燥が得意な真空乾燥機、粉砕・分級も同時に行うドライマイスター、原料スラリーを瞬時に噴霧乾燥するスプレードライヤー等がございます。

[parent] => 12

[count] => 12

[filter] => raw

[term_order] => 1

)

)

[41] => Array

(

[detail] => WP_Post Object

(

[ID] => 237

[post_author] => 1

[post_date] => 2019-04-01 16:29:00

[post_date_gmt] => 2019-04-01 07:29:00

[post_content] =>

[post_title] => ラボプログラム制御 マッフル炉 (FO510MAX1150℃)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => _fo510max1150

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:28:58

[post_modified_gmt] => 2023-09-13 09:28:58

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/_fo510max1150/

[menu_order] => 46

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 9

[name] => 焼成

[slug] => heat-heat

[term_group] => 0

[term_taxonomy_id] => 9

[taxonomy] => equipment_category

[description] => 焼成は、製品に強度を与えたり(硬質にする)、色味の調整、不要な成分を除去する役割があります。日本カラー工業にある焼成設備の中でも、ローラーハースキルンは、上下から均一に加熱、窒素雰囲気下で焼成することもでき、製品の酸化を防ぐことが可能です。他焼成設備もございますので、ぜひ設備一覧をご覧ください。

[parent] => 8

[count] => 3

[filter] => raw

[term_order] => 1

)

)

[42] => Array

(

[detail] => WP_Post Object

(

[ID] => 221

[post_author] => 1

[post_date] => 2019-04-04 14:59:00

[post_date_gmt] => 2019-04-04 05:59:00

[post_content] =>

[post_title] => Vブレンダー

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => v

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-12 17:23:40

[post_modified_gmt] => 2023-09-12 08:23:40

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/v/

[menu_order] => 47

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 4

[name] => 粉体混合

[slug] => fusion-powder

[term_group] => 0

[term_taxonomy_id] => 4

[taxonomy] => equipment_category

[description] => Vブレンダー、リボンブレンダー、ヘンシェルミキサ―など各種混合設備を使用し、原料(粉体)特性に合わせた均一な混合が可能です。少量向けのサイズもあり、試作・ラボテストから使用することができます。

[parent] => 2

[count] => 4

[filter] => raw

[term_order] => 2

)

)

[43] => Array

(

[detail] => WP_Post Object

(

[ID] => 239

[post_author] => 1

[post_date] => 2019-04-01 15:12:00

[post_date_gmt] => 2019-04-01 06:12:00

[post_content] =>

[post_title] => チラーユニット

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_31

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:22:47

[post_modified_gmt] => 2023-09-13 09:22:47

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_31/

[menu_order] => 48

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 11

[name] => ユーティリティー

[slug] => utilities

[term_group] => 0

[term_taxonomy_id] => 11

[taxonomy] => equipment_category

[description] => 生産に必要なイオン交換水を精製する純水装置、各種設備のオーバーヒートを防ぐチラーユニット、環境基準をクリアした排水を行うための排水処理(一部は廃水処理業者様へ依頼する場合もございます)を行っています。安定した受託生産に不可欠な、徹底管理したユーティリティー設備が揃っています。

[parent] => 8

[count] => 3

[filter] => raw

[term_order] => 3

)

)

[44] => Array

(

[detail] => WP_Post Object

(

[ID] => 240

[post_author] => 1

[post_date] => 2019-04-01 15:05:00

[post_date_gmt] => 2019-04-01 06:05:00

[post_content] =>

[post_title] => 反応槽FRP

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => frp

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:24:49

[post_modified_gmt] => 2023-09-13 09:24:49

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/frp/

[menu_order] => 49

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 10

[name] => 反応層

[slug] => heat-reaction

[term_group] => 0

[term_taxonomy_id] => 10

[taxonomy] => equipment_category

[description] => 36L容量のタンク~耐酸性に優れたGL(グラスライニング)層まで幅広いラインナップ。ジャケット付きのタンク・反応層もございますので、液体原料を加温することも可能です。

[parent] => 8

[count] => 3

[filter] => raw

[term_order] => 2

)

)

[45] => Array

(

[detail] => WP_Post Object

(

[ID] => 241

[post_author] => 1

[post_date] => 2019-04-01 15:02:00

[post_date_gmt] => 2019-04-01 06:02:00

[post_content] =>

[post_title] => マゼラー

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_24

[to_ping] =>

[pinged] =>

[post_modified] => 2023-11-21 14:09:21

[post_modified_gmt] => 2023-11-21 05:09:21

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_24/

[menu_order] => 50

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 4

[name] => 粉体混合

[slug] => fusion-powder

[term_group] => 0

[term_taxonomy_id] => 4

[taxonomy] => equipment_category

[description] => Vブレンダー、リボンブレンダー、ヘンシェルミキサ―など各種混合設備を使用し、原料(粉体)特性に合わせた均一な混合が可能です。少量向けのサイズもあり、試作・ラボテストから使用することができます。

[parent] => 2

[count] => 4

[filter] => raw

[term_order] => 2

)

)

[46] => Array

(

[detail] => WP_Post Object

(

[ID] => 243

[post_author] => 1

[post_date] => 2019-03-31 16:30:00

[post_date_gmt] => 2019-03-31 07:30:00

[post_content] =>

[post_title] => スプレードライヤー(4号機)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_32

[to_ping] =>

[pinged] =>

[post_modified] => 2024-11-15 16:02:18

[post_modified_gmt] => 2024-11-15 07:02:18

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_32/

[menu_order] => 52

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 14

[name] => 乾燥

[slug] => dry-dry

[term_group] => 0

[term_taxonomy_id] => 14

[taxonomy] => equipment_category

[description] => 原料(湿粉、スラリー)に熱風、蒸気、温水(間接加温)を使って水分を蒸発させます。数多くの設備を所有する日本カラー工業の中でも、特に乾燥設備は種類が豊富。熱に弱い原料の乾燥が得意な真空乾燥機、粉砕・分級も同時に行うドライマイスター、原料スラリーを瞬時に噴霧乾燥するスプレードライヤー等がございます。

[parent] => 12

[count] => 12

[filter] => raw

[term_order] => 1

)

)

[47] => Array

(

[detail] => WP_Post Object

(

[ID] => 244

[post_author] => 1

[post_date] => 2019-03-31 15:18:00

[post_date_gmt] => 2019-03-31 06:18:00

[post_content] =>

[post_title] => 横型フィルター反転式遠心分離機

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_33

[to_ping] =>

[pinged] =>

[post_modified] => 2023-09-13 18:21:28

[post_modified_gmt] => 2023-09-13 09:21:28

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_33/

[menu_order] => 53

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 7

[name] => 脱水・洗浄

[slug] => clean-dry

[term_group] => 0

[term_taxonomy_id] => 7

[taxonomy] => equipment_category

[description] => 日本カラー工業でできる脱水(固液分離)・洗浄は、少量・難濾過性原料向けの上排型脱水機や横型フィルター反転式遠心分離機、一度に多くの処理量が求められる製品にはフィルタープレスがあります。無機、有機問わず反応後の未反応物や不純物を取り除いたり、また、固形濃度が低いスラリーからの製品回収にも効果を発揮します。

[parent] => 6

[count] => 3

[filter] => raw

[term_order] => 1

)

)

[48] => Array

(

[detail] => WP_Post Object

(

[ID] => 245

[post_author] => 1

[post_date] => 2019-03-30 10:18:00

[post_date_gmt] => 2019-03-30 01:18:00

[post_content] =>

[post_title] => スプレードライヤー(5号機)

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => post_34

[to_ping] =>

[pinged] =>

[post_modified] => 2024-07-12 08:17:11

[post_modified_gmt] => 2024-07-11 23:17:11

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.nc-ind.com/wp/equipment/post_34/

[menu_order] => 54

[post_type] => equipment

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[taxonomy] => WP_Term Object

(

[term_id] => 14

[name] => 乾燥

[slug] => dry-dry

[term_group] => 0

[term_taxonomy_id] => 14

[taxonomy] => equipment_category

[description] => 原料(湿粉、スラリー)に熱風、蒸気、温水(間接加温)を使って水分を蒸発させます。数多くの設備を所有する日本カラー工業の中でも、特に乾燥設備は種類が豊富。熱に弱い原料の乾燥が得意な真空乾燥機、粉砕・分級も同時に行うドライマイスター、原料スラリーを瞬時に噴霧乾燥するスプレードライヤー等がございます。

[parent] => 12

[count] => 12

[filter] => raw

[term_order] => 1

)

)

)

設備・計測器を検索

化学品の外部委託をお考えのお客様は受託専門の日本カラー工業へご相談ください。最適なご提案と用途に応じた各種設備・装置でサポートいたします。